Tips to Help you Hurdle those Common Basement Finishing Obstacles

Prioritizing large inventories of the highest quality products, RapidAir provides single-source solutions supported by a world class customer service and technical support team that helps you effortlessly get quotes, meet specifications, design and install your compressed air systems. GET A QUOTE

How to Run an Airline KITPLANES

QUICKLY TRANSFORM YOUR GARAGE WITH RAPIDAIR EXPRESS MASTER KITS Nothing beats opening a box and have everything you need to have a working compressed air system for your shop or garage.

Quincy air compressor and air line manifold system pt 1 YouTube

Incorrect air pressure: Many companies use their air tools with too low or an incorrect set air pressure.The performance of the tool is reliant on a correct setup of the air infrastructure. Selection of wrong pneumatic equipment: Wrong dimensioned hoses and old pneumatic equipment are usually overlooked in a compressed air system, and is often the main source of the problem.

The Best Air Compressor Pipe for Your Air Compressor? JHFoster Blog

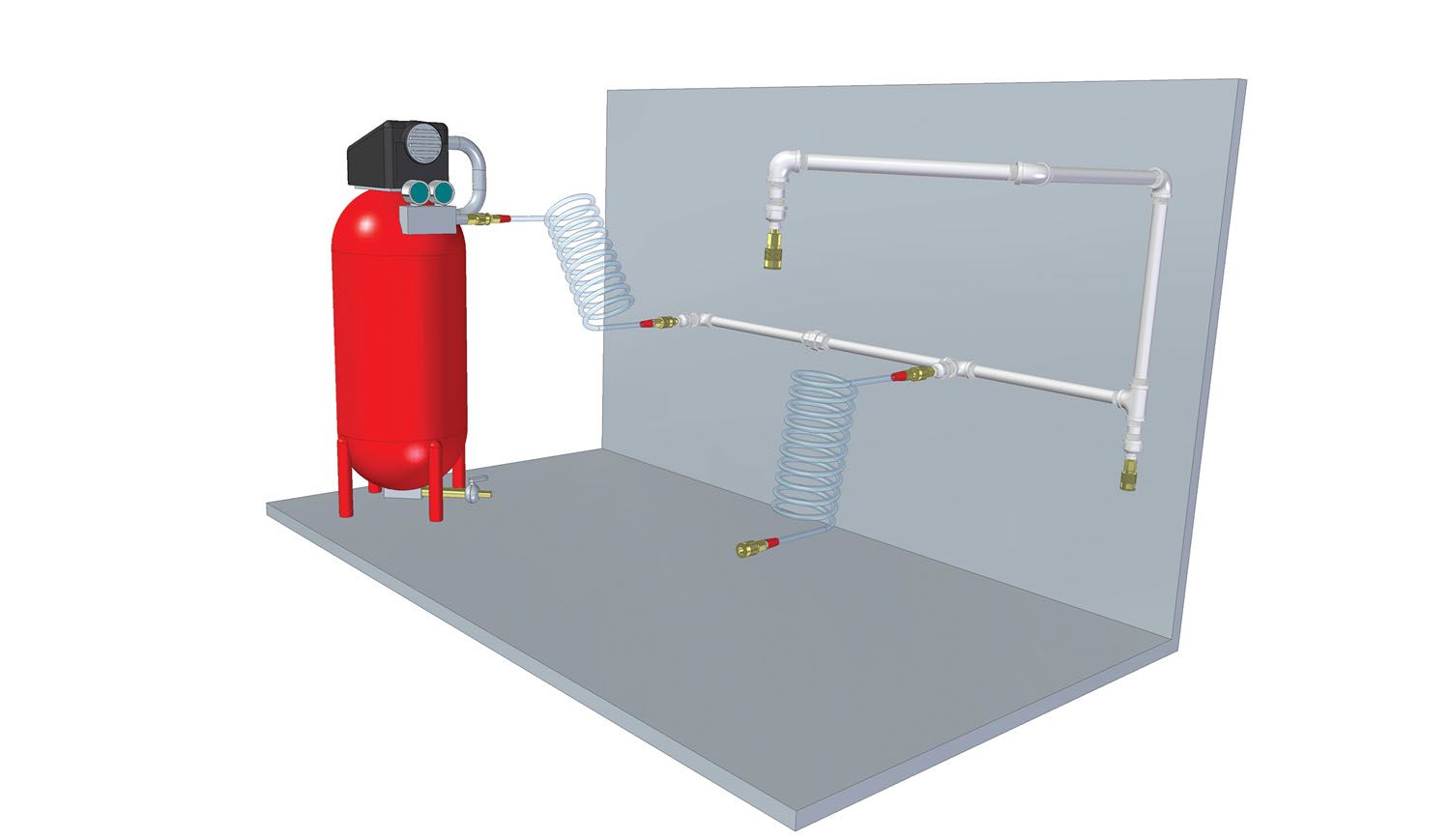

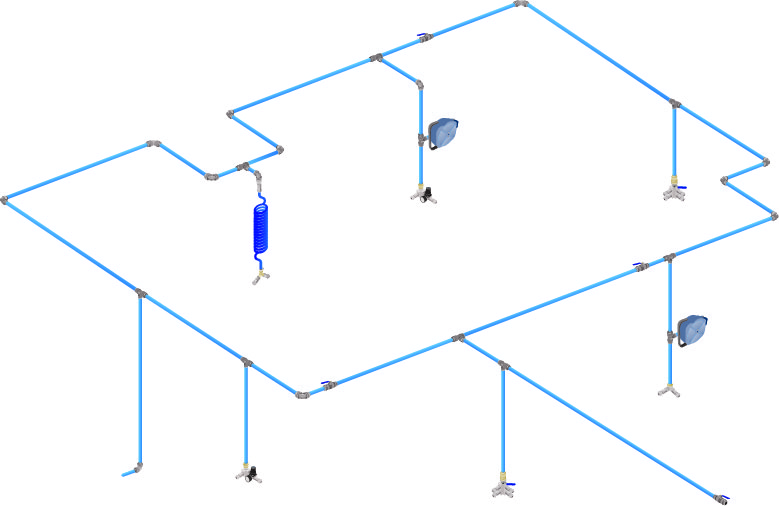

The very first step to effectively running air compressor lines in a garage space is planning out your optimum layout, and this will largely depend on where you intend to use the compressed air and the number of drops you plan to include in the setup.

Air Piping System McGee Company

Installations For your compressed air system installation, Ingersoll Rand is your single source provider, with: Design service - determine system requirements, equipment selection, and air system layout Equipment provider - compressors, dryers, cooling towers, receiver tanks

Compressed Air System Install Hot Rod Network

Central air installation costs an average of $5,861; the typical range runs from $3,882 for smaller systems to $7,905 for larger or upgraded systems, according to HomeAdvisor.

Compressed air Piping Installed By VIRAL ENTERPRISE YouTube

Contact IMS Compressed Air Line Installation Why do you need compressed air line system for your commercial space and industrial facilities? The main purpose of compressed air piping system is that it delivers compressed air from one place to another.

How To Run Air Lines In A Shop Shop Poin

Products and Solutions Compressed air piping Aluminum Compressed Air Piping Aluminum Piping: SmartPipe Compressed Air Piping System Kaeser's SmartPipe™ is a modular pipe for compressed air installations. SmartPipe offers both lower installation costs and lower long-term operating costs.

Air compressor pipe installation stepsGuangdong Foster Fluid Technology Co., LTD. Websiteair

While solid and robust, aluminum AIRnet pipe weighs five times less than galvanized pipes. That is why only one person is needed to safely handle and install them. Traditional piping assembly requires at least two mechanics, due to the heavy materials and the use of large and complex tools. [/vc_column_text] [/vc_column] [/vc_row] [vc_column.

How to Install Air Compressor Lines in Garage

The RapidAir 3/4in. MaxLine compressed air piping system is designed for high-demand air tool users and longer air line runs in large buildings. It features high-density polyethylene (HDPE) tubing with an aluminum core to maintain any hand-bent shape for easy wall installation. 200 PSI operating pressure at 70°F; 140 PSI at 140°F.

DIY Garage / Shop Air Lines RapidAir Maxline adding a new air line drop YouTube

Drill a 5/16" hole where you plan to mount the inflation valve (s). If installing a single-path setup, find a desired tee location on the frame rail or cross member and determine and cut adequate length of air line to reach the tee from the left and right air springs.

AIR COMPRESSOR SALES AND SERVICE air line installation, compressed air lines, air compressor

RapidAir FastPipe tubing provides a clean, straight and reliable compressed air piping system for your shop or industrial application.. Total 500ft Compressed Air System Installation Cost. $5,538. 185% more than FastPipe. $6,449. 215% more than FastPipe. $2,997. Other considerations. Material Familiarity + Popularity. Ongoing Maintenance.

Air Line Installation Nessco Pressure Systems

How to set up my air line correctly. After all, pneumatic tools need air to work! There are 3 simple steps to make sure your air line installation is providing the right pressure and that your accessories selection is correct, so you can ultimately work productively. It does not take long and it is something you can easily do yourself using our self-diagnostic checklist.

AIR LINE INSTALLATION AND FACILITY MAINTENANCE Hydroflex Technical Services

Installing your compressed air line with the best types of pipes can extend the longevity of your system. Follow the compressed air line installation tips below: Choosing pipe materials - You should use aluminum compressed air pipes in your systems as they are more durable and require less maintenance than their counterparts. While at an.

AIR LINE INSTALLATION AND FACILITY MAINTENANCE Hydroflex Technical Services

There is a simple way to reduce moisture in the piping system : change the compressor's supply inlet source. The water resulting from compression weighs more than compressed air, which causes it to sink. If air is drawn in from the compressor's top, less moisture will be sucked in with it.

About Compressed Air Lines Understanding Air Compressors

About Air Line Installation Are you in need of compressed air line piping service at your facility? The C-Aire service and maintenance team is here to help! We can perform air system inspections with our Fluke ii900 precision acoustic imager, as well as compressed air line piping installations.